Environmental and financial benefits of Cummins’ EPA Tier 2 to Tier 4 engine conversion solution

By Aytek Yuksel, Content Marketing Leader - Power Systems

The Environmental Protection Agency (EPA) has been aggressively reducing diesel engine emissions over the last 25 years, and Cummins Inc. has committed to developing the technology to meet these requirements. These regulations have been embraced within the oil & gas industry, as the sector continues the journey to reduce its environmental impact.

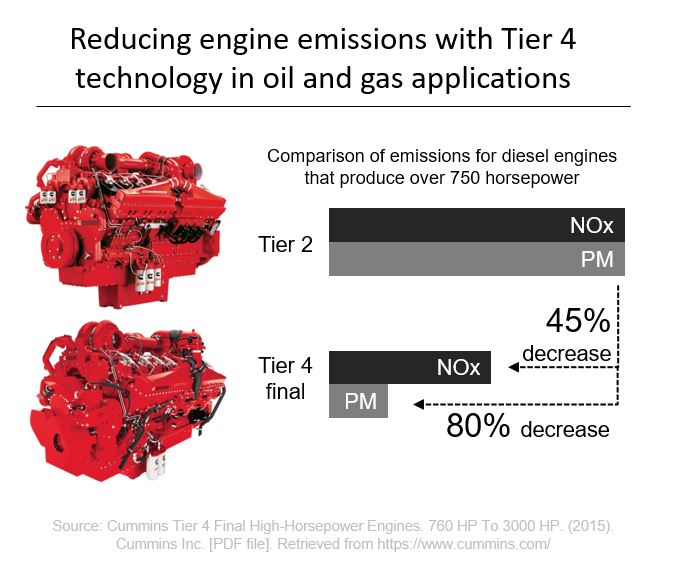

The EPA’s latest Tier 4 final emission regulations applicable for oil and gas industry represent a significant step towards further reducing nitrous oxides (NOx) and particulate matter (PM). For example, the Cummins QSK50 Tier 4 for well-servicing produces 45% less nitrous oxides and 80% less particulate matter than its EPA Tier 2 predecessor.

If you are an oilfield service company with an existing fleet of Cummins QSK50 Tier 2 engines, the path to Tier 4 emissions is simpler than you might think. You can transition the Tier 2 engines within your fleet to Tier 4 and enjoy the environmental benefits in an economical way.

You can simply utilize the Tier 2 to Tier 4 conversion solution on your existing Cummins QSK50 Tier 2 engines at the time of rebuild instead of replacing and scrapping your current engines.

Let’s look at the environmental and economic benefits of converting your Tier 2 engines to certified Tier 4 engines.

Reducing the engine emissions with Tier 4 compliant technology in oil and gas applications

Tier 4 final emission standards, in comparison to Tier 3 and Tier 2, represent a significant step towards reducing nitrous oxides (NOx) and particulate matter (PM), key ingredients found in smog. Whether you use the Tier 2 to Tier 4 conversion solution or use brand new Tier 4 engines, your business will still materialize the benefits on engine emission reduction.

Reducing oil and gas sector’s environmental impact beyond engine emissions

Beyond the reduced engine emissions, there is another important environmental benefit of applying the Tier 2 to Tier 4 conversion solution on your Cummins QSK50 engines: reducing scrap metal and equipment.

The conversion allows you to extend the use of your existing engine and frac rig. For example, you can sustain the longevity of your engine core and save the one or two overhaul lives left in your Tier 2 engines while meeting your emissions goals.

This environmental benefit could be bigger than you think. Scrap metal, when not recycled, fills up the landfills. In the U.S. alone, over 50 million tons of steel is scrapped a year. While 80% to 90% of this gets recycled, the rest accumulates within the landfills. The accumulation of scrap metal in landfills could pollute the nearby soil and water supplies. Scrap metals also create an increased need for mining minerals that can then be refined to metals. This mining and refining is an energy-intensive process.

Lowering the capital expenditures of oilfield service companies

If you already have Cummins Tier 2 engines within your well-servicing equipment, there are two ways to make the transition to Tier 4 engines.

The first option is to purchase a new Cummins QSK50 Tier 4 engine which offers the same reliability and durability demonstrated by the Cummins QSK50 Tier 2. This is because the selective catalytic reduction (SCR) aftertreatment technology allows Cummins to use the known QSK50 platform while still achieving the lowest diesel emissions in the market. If you opt to go this route, the equipment transition is easy due to the similar footprint and low heat rejection of this certified engine.

Another more economical option, if you have Cummins QSK50 Tier 2 engines, is to upfit to Tier 4 content at the time of rebuild. These conversions are performed at Cummins Master Rebuild Centers by trained and certified technicians.

There are three ways the Tier 2 to Tier 4 conversions can lower your capital expenditures (CapEx).

- Lowering the CapEx on new frac rigs. You can extend the life of existing fleets by refurbishing them and utilizing the engine conversion offering.

- Lowering the CapEx on new engines. You get the latest emission certified engines, without the cost of buying a new engine.

- Lowering the CapEx on cooling packages. The SCR aftertreatment technology used to achieve Tier 4 emissions allows the engine systems to maintain a low heat rejection which removes the need to invest in a new cooling package for your equipment.

Generating more revenue using your existing engines and equipment

If you are participating in time-sensitive bids that call for Tier 4 equipment, the longer lead times associated with a new engine purchase could mean lost revenue if your upgraded equipment won’t be ready in time.

With a Tier 2 to Tier 4 conversion solution, the time to upgrade your equipment could be reduced. And with shorter lead times comes your business' ability to participate in near term bids.

You can achieve and generate more revenue from your oil and gas equipment with these reduced lead times.

Decreasing the capital expenditures, helping your business generate more revenue, and reducing your business' environmental impact. These are the three key benefits of the Tier 2 to Tier 4 conversion solution for Cummins QSK50 engines used in oil and gas applications.

Interested in more oil and gas perspectives? También puede interesarle:

- What is a dual fuel engine, and its benefits for oil and gas applications?

- Drilling pads with lower OpEx, reduced carbon footprint and higher safety

- Reducing greenhouse gas emissions of engines in the oil and gas sector for improved sustainability

To learn more about oil and gas power solutions Cummins offers, visit our webpage.

Author Profiles

Aytek Yuksel, Content Marketing Leader - Power Systems

Aytek is a marketing leader at Cummins, focusing on technology and thought leadership. Since joining in 2008, he has held various marketing roles and now shares insights on markets, technologies, and energy transition. Aytek lives in Minneapolis with his wife and two kids.

Related Tags