What are the functions of the Electronic Control Module (ECM)?

By Cummins Components Business Unit

An engine's performance depends on both the parts you can see and the technology that you cannot. That's where the Electronic Control Module (ECM) comes in. The ECM is the brain of the engine, optimizing performance and efficiency while managing key safety and operational systems in both on-highway and off-highway vehicles.

This article explains the functions of the ECM and how it optimizes engine performance, reliability and efficiency.

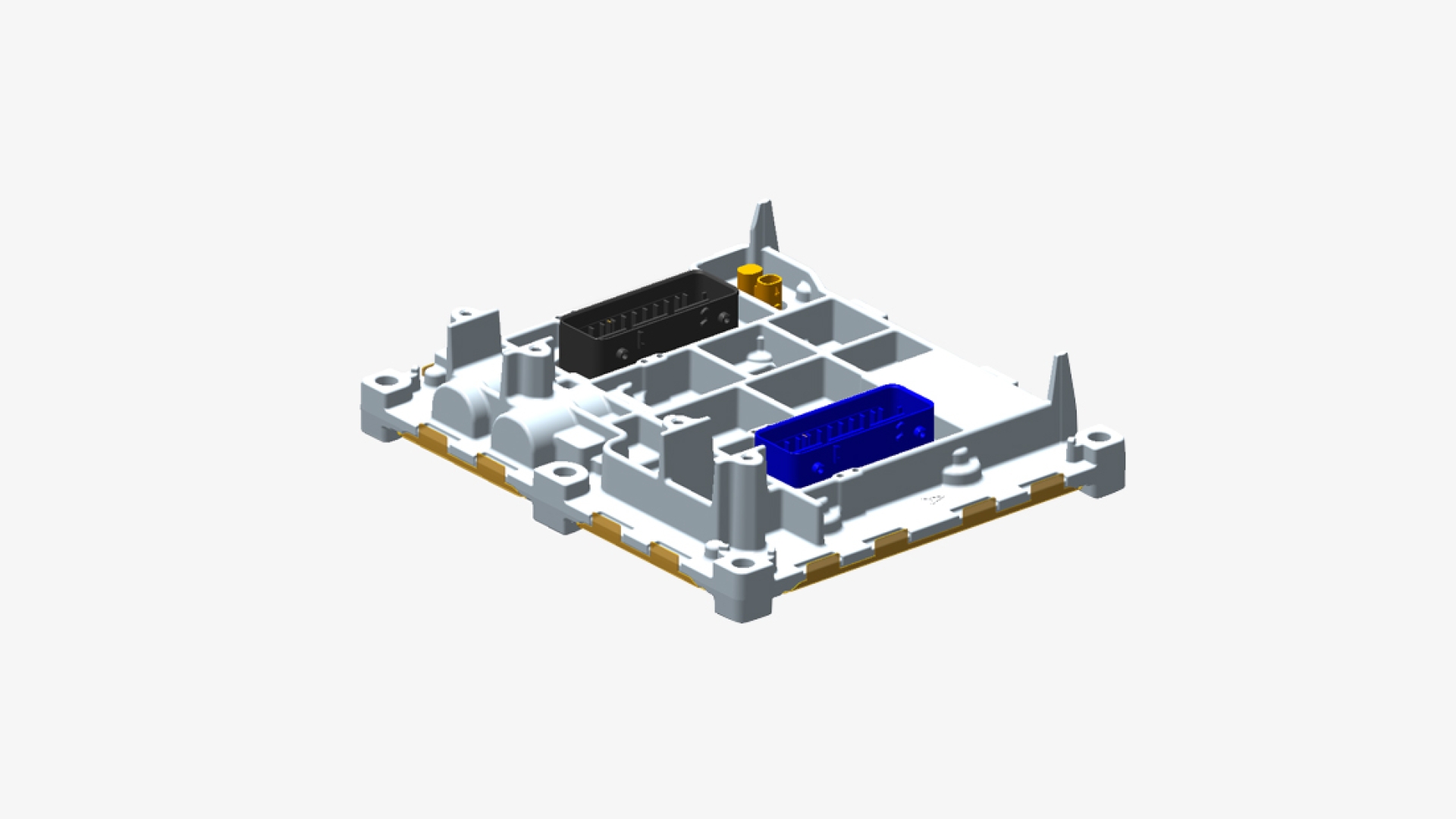

What is the Electronic Control Module (ECM)?

The ECM is the heart of a modern engine. The ECM collects data from sensors distributed across the engine and uses this to analyze performance in real time. This data provides the ECM with key insights and enables adjustments for fuel consumption, ignition timing, achieving maximum engine efficiency, improving fuel economy and overall performance.

Beyond this, the ECM is crucial for maintenance and troubleshooting. When the engine encounters issues, the ECM quickly identifies and records the problem using specific diagnostic codes. These codes, accessible with professional tools, help to identify problems quickly and accurately, preventing further damage and expensive downtime.

For both on-highway and off-highway applications, the ECM is invaluable. On-highway vehicles can enjoy enhanced fuel efficiency, reduced costs and increased profitability. Off-highway applications often face harsh terrains where the engine's optimal performance is crucial. With the ECM’s ability to ensure optimal engine operation and quick diagnostics, engines can operate at their highest level across many applications.

What are the functions of the Electronic Control Module (ECM)?

So how does the Electronic Control Module help an engine run? Here is an overview of the functions of an ECM including what it monitors and manages, and how it helps on-highway and off-highway applications operate at peak performance.

- Manages engine performance: A crucial job of an Electronic Control Module is to monitor and adjust engine operations. It fine-tunes the fuel injection system, ignition timing, and many other engine functions. By constantly analyzing data from different sensors, it improves performance and efficiency. For instance, while driving uphill, a truck's engine experiences a higher load and lower speed. The ECM detecting these changes through sensors, adjusts the fuel injection and ignition timing accordingly. This optimization ensures the engine provides the necessary power efficiently, helping the truck to climb smoothly without overworking the engine or wasting fuel.

- Monitors and helps control emissions: Electronic Control Modules play a vital role in emissions reduction and managing engine pollutants by constantly monitoring the engine's exhaust through sensors. If the ECM detects an increase in pollutant levels, it adjusts the engine's operations, such as the fuel-air mixture and combustion timing, to reduce emissions. ECM also constantly monitors temperatures, pressure and chemical compositions of the engine exhaust gas through sensors. It analyzes this information and takes action to operate the exhaust gas aftertreatment systems like Particulate Filter System (PFS) and Selective Catalytic Reductant (SCR) at optimal conditions. Broader use of engines equipped with ECMs can help the transportation sector lower its carbon and greenhouse gas emissions. You can read more about various other strategies employed to reduce transportation emissions.

- Helps with transmission control: The ECM is central to efficient transmission operations. It monitors factors like vehicle speed, engine load and driver input to optimally time the gear shifts. For example, when a truck is hauling a heavy load uphill, the ECM can detect the need for more torque to navigate the incline efficiently and can delay the shifting of gears in the transmission. This optimization ensures the engine delivers sufficient power while maintaining optimal fuel efficiency.

- Monitors the braking system: Road safety is critical, and the ECM helps by monitoring and managing the anti-lock braking system and other brake-related functions. If it detects a wheel is about to lock up, the ECM modulates the brake pressure to that wheel, preventing skidding and maintaining vehicle control. This ensures optimal brake control, enhancing safety for all driving conditions.

- Monitors the safety systems: The ECM also monitors various safety systems in the vehicle. It manages airbags, seatbelt pre-tensioners, and other safety features. In a collision, for example, it determines when to deploy airbags and tighten seatbelts to minimize possible injuries.

- Helps control vehicle accessories: The ECM controls vehicle accessories, from power windows and climate control to entertainment systems. It ensures these systems function well and seamlessly interact with other vehicle systems. For example, it might modify the climate control based on engine temperature and cabin conditions for increased driver comfort.

How does the Electronic Control Module (ECM) work with different technologies?

ECM components in diesel, Hydrogen Internal Combustion Engines, and BEVs/FCEVs share similarities. Yet, in BEVs and FCEVs, ECM components need specialized design for handling high voltage and current applications.

In a Fuel Cell Electric Vehicle (FCEV), the ECM additionally controls and monitors systems such as the hydrogen supply, air system, thermal and water management systems, and storage system.

Explore Cummins’ range of Electronic Control Modules that can help operators across a variety of applications. Cummins Inc.’s ECMs can work with diesel, natural gas, battery electric, fuel cell technology as well as after-treatment systems. If you are interested in learning more, please reach out to us.

Author Profiles

Temas relacionados

Related Tags