What are power-to-x and e-fuels?

As more businesses focus on reducing their environmental footprint, the interest in alternative fuels, power-to-x, and e-fuels continues to rise. Today, many varieties of e-fuels are used in power generation applications and beyond. Let's start with basics around power-to-x and e-fuels.

By Aytek Yuksel, Content Marketing Leader - Power Systems

What is power-to-x?

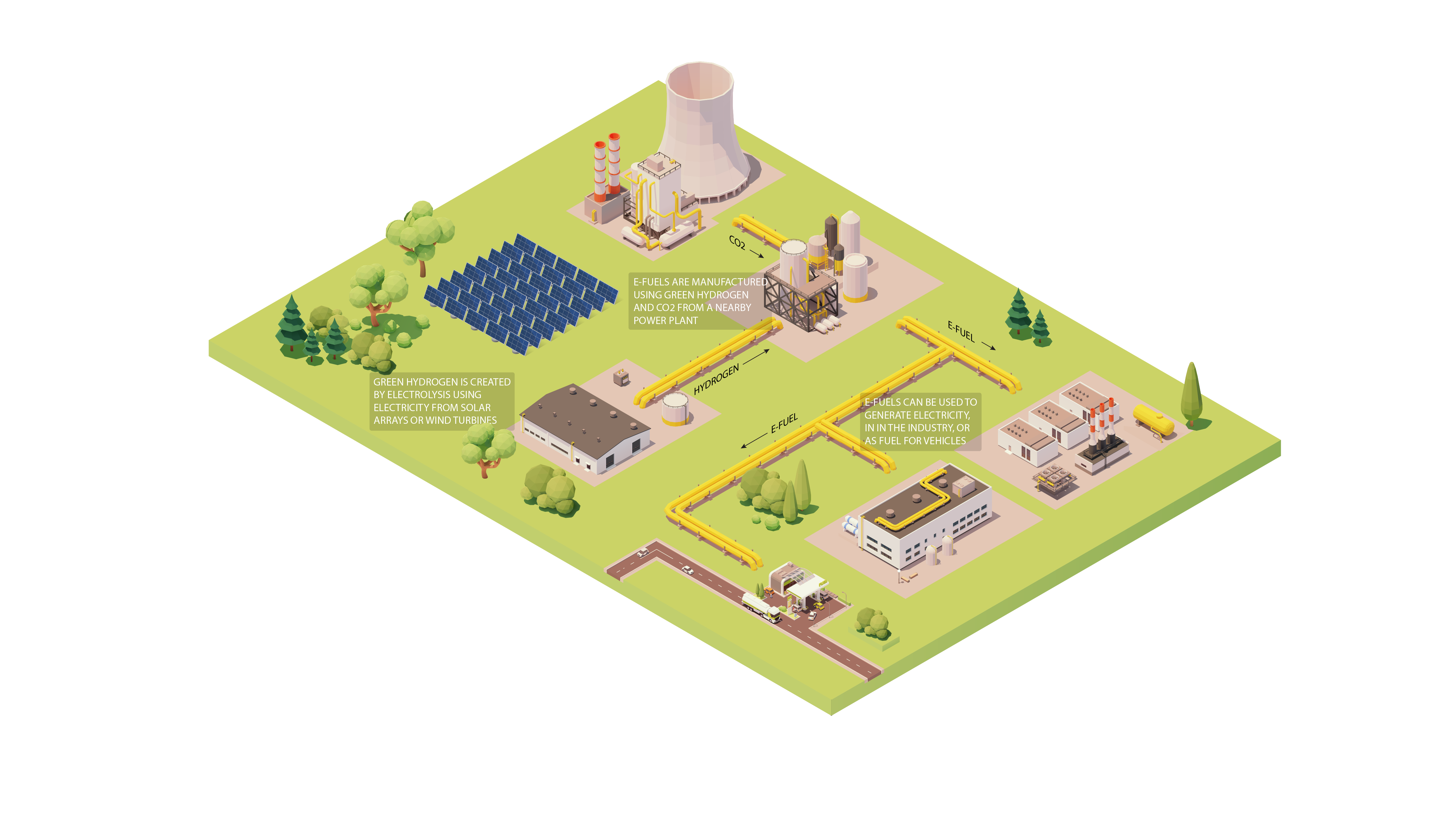

"Power-to-x" refers to a series of techniques and pathways allowing to convert, store and utilize renewable electrical energy. Power-to-x is specifically applicable when there is an excess of renewable electricity produced from solar or wind resources. Rather than be wasted-the specific industry term for this is "curtailed"-the excess electricity is used productively. The "x" can refer to a variety of energy carriers or uses. Power-to-hydrogen is the generation of hydrogen using renewable electricity. Power-to-power refers to storing electricity in batteries. Power-to-heat consists of using electricity to heat a home or a business, typically coupled with a heat accumulator. The meaning of power-to-methane should be easy to guess.

What are e-fuels?

E-fuels are fuels that are synthetized using renewable electricity, often using inorganic feedstock. They're the "x" of power-to-x when "x" is a fuel. E-fuels include liquid and gaseous hydrocarbons such as methane and various gasoline-like, diesel-like fuels, alcohols such as ethanol and methanol, and non-carbon fuels such as hydrogen and ammonia.

Why do we need e-fuels and power-to-x?

Power-to-x system allow to decouple electricity generation and electricity demand. At each instant, the total amount of electricity generated on an electricity grid must precisely match the total amount of electricity used by consumers. In other words, generation and demand are normally closely coupled. If generation is unable to keep up with demand, for example if too many power-plants trip at the same time, the electric grid can quickly collapse. Counterintuitively, the same is true if generation exceeds demand. When large quantities of variable renewable energy resources such as wind and solar are online, renewable generation can rapidly exceed demand. When this occurs, renewable resources get curtailed to avoid collapsing the system.

In some markets, the spot price of electricity can, as a result, become negative when renewable generation is high. This means that market participants get paid to use more electricity.

Power-to-x projects take advantage of excess and off-peak renewable power to produce something useful. It's a win-win situation-power-to-x producers can buy cheap renewable CO2-free electricity and solar and wind farms get to sell electricity that would otherwise have been lost.

E-fuels produced at a power-to-x project can be used hours, weeks or months later to produce electricity.

E-hydrogen, for example, can be used in a business equipped with a fuel cell and solar panels to make electricity during the evening and night. Business can use this setup to reduce demand fees charged by the electric utility to consumers with a high peak demand.

At the grid level, e-hydrogen can be stored seasonally. The city of Los Angeles, California (U.S.) for example, is sponsoring a large power-to-hydrogen-to-power project in Utah. The project will create hydrogen using electricity from nearby wind and solar resources. During summer, the hydrogen will be stored underground in a geological formation. During winter, the hydrogen will be used to generate electricity, which will then be transported directly to Los Angeles via an existing high voltage transmission line.

For electricity consumers, e-hydrogen are a way to reduce their carbon footprint beyond what can be achieved with solar arrays and wind turbines alone. For utility companies and grid system operators, e-hydrogen is especially valuable, because it is one of the few CO2-free ways to balance out intermittent variable renewable energy resources.

The benefits of using e-fuels are not limited to the power generation application. They can be used in vehicles and other industrial sectors to great advantage. Forklifts running on e-hydrogen are one e-fuel application that has become popular in the logistics sector, and e-hydrogen forklifts check several boxes. They have little downtime. They don't generate any fumes or exhaust, and in an enclosed environment like a warehouse, this feature is important. And, they're CO2-free.

Beyond e-hydrogen, liquid e-fuels have a different process to be produced, which is more complicated. These liquid e-fuels are especially useful to power up heavy-duty applications such as marine applications.

For applications where hydrogen is not a practical option, several alternative e-fuels can be synthesized using hydrogen. Here are some of the main ones:

What is e-methanol?

Methanol is a commodity product used on a large scale in the chemical industry to produce a variety of substances. Methanol is sometimes known as wood alcohol, and has long been used as a fuel in specialty vehicles such as RC aircraft, dirt bikes, and, yes, monster trucks. Several processes have been developed to synthesize methanol using CO2, hydrogen, and renewable electricity. Their product is a clean, carbon-neutral energy carrier—e-methanol. There is growing interest in using methanol as a marine fuel. Methanol and e-methanol could help tugboats, fishing boats, ferries and other vessels using specially modified engines to meet increasingly strict regulations limiting emissions of NOx and sulfur in densely populated coastal areas, and, in the case of e-methanol, also decrease their carbon footprint.

What is e-methane?

Methane, the main constituent of natural gas, is a widely used fossil fuel. In the United States, methane is the number one energy source used in power generation. Methane and natural gas are also increasingly popular fuels for motor vehicles. A power-to-methane system combines an e-hydrogen production process with CO2 to produce carbon-neutral e-methane. Several e-methane production processes are being developed and industrialized. Outside of power generation, the mining sector has shown a great deal of interest in these processes. For mines located in remote areas, the cost of trucking in gasoline or diesel can be prohibitively high. These mines can potentially save a lot of money by fueling their heavy hauler trucks with e-methane on-site, using renewable electricity generated locally.

What is e-diesel?

Companies and research institutions around the world are developing processes to mass produce liquid hydrocarbons from CO2, and water using e-hydrogen. The production of synthetic gasoline, jet fuel and diesel is envisioned. One advantage of these e-fuels is they can be used as a drop-in fuel in standard engines, making CO2-neutral operation possible without needing any modification to the vehicles or fueling infrastructure.

What is e-ammonia?

Ammonia is another very common chemical. The fertilizer industry uses it in vast quantities, and it has seen occasional use as a fuel in specific situations. Belgium, for example, converted city buses to run on ammonia during World War II (the buses were scrapped as soon as fossil fuels became available again).

In the 1960s NASA flew the X-15 rocket-powered aircraft using ammonia as fuel. Producing ammonia from hydrogen is a well-established process. Ammonia, or e-ammonia, could thus be produced industrially without any CO2 emissions in a power-to-hydrogen-to-ammonia system. E-ammonia is seen as a potential alternative to hydrogen, being easier to store and transport. Like hydrogen, ammonia can be used in specially designed fuel cells, internal combustion engines and gas turbines without releasing any emissions.

E-fuels show promise, but all must still overcome challenges preventing their widespread adoption. In almost all cases, production costs are the main issue. Outside of certain specific use cases, there are often other low CO2 alternatives available that e-fuels must compete with. Biofuels and electric batteries have a head start in that regard, having been on the market longer.

Infrastructure costs are another challenge, particularly in the case of the non-hydrocarbon e-fuels. Fewer ships can adopt methanol if methanol is not widely available at ports. Costs, however, will come down as e-fuel technology matures and production scales increase. To make a parallel, the cost of lithium-ion batteries (the type used in electric vehicles and most stationary energy storage) has fallen by 98% in the past 30 years. If e-fuels experience a fraction of that progression, it will not be long before you can find them at your local gas station.

In addition to e-fuels, don’t forget to check out what the low-carbon fuels are, and the benefits of alternative fuels and fuel-flexibility.

Power-to-x, e-fuels, and your business

You are likely already centering your frame of thinking on the needs of your business, and asking yourself how these different alternative fuels can play a role to fulfill your needs.

In addition to the fuel itself, consider taking local availability, regulations, and your use case into account too. These additional factors compliment the unique benefits each alternative fuel offers.

These additional factors are also locally driven. If you are interested in having a discussion specific to your business, we recommend you reach out to a local partner with deeper understanding of your business and needs.

Author Profiles

Aytek Yuksel, Content Marketing Leader - Power Systems

Aytek is a marketing leader at Cummins, focusing on technology and thought leadership. Since joining in 2008, he has held various marketing roles and now shares insights on markets, technologies, and energy transition. Aytek lives in Minneapolis with his wife and two kids.