ELIMINATOR

Available on the KTA38, KTA50, and all QSK MCRS engines, ELIMINATOR is a combination full-flow and centrifugal system that incorporates a permanent stainless steel core that eliminates the need for disposable oil filters.

Available on the KTA38, KTA50, and all QSK MCRS engines, ELIMINATOR is a combination full-flow and centrifugal system that incorporates a permanent stainless steel core that eliminates the need for disposable oil filters.

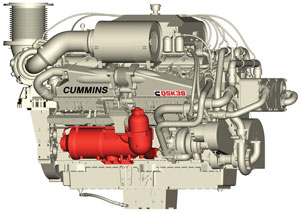

ELIMINATOR (outlined in red in the photo) consists of a two-stage filter media system. The first filter screens for particles as small as 20 microns, while a centrifugal separator constantly spins, depositing the heaviest particles on a replaceable liner.

Because ELIMINATOR uses the oil pressure in the lubricating system to spin the centrifugal separator, there is no additional load on the engine, with no drain on power or fuel economy. This option lowers the cost of operation by:

- Eliminating the recurring cost and maintenance of spin-on filters

- Reducing downtime for filter changes

- Eliminating disposal cost of used filter elements

- Improving filtration and reducing component wear which can extend overhaul periods

- Extending oil change intervals when used concurrently with oil sampling and CENTINEL

ELIMINATOR satisfies most Marine Classification Society requirements for duplex filters.