Welcome to the era of smarter, cleaner power

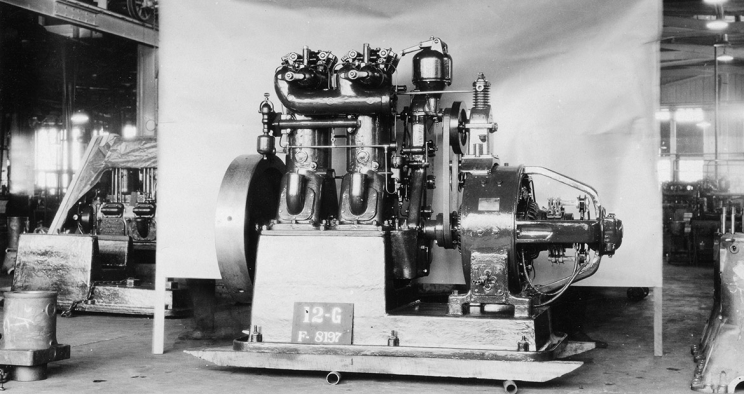

The diesel engine working principle was completed by the inventor, Rudolf Diesel, in 1892, and the first prototype was created in 1897. In the years following, he continued to work on improving his theory, and others soon realized the potential of this invention and started making their own versions. One of the people to recognize the importance of the diesel engine was Clessie Lyle Cummins. In 19

Rudolf Diesel and Clessie Cummins have many things in common. The most notable being their desire to find efficient solutions to problems with one goal in mind - making the world a better place. The invention of advanced diesel engines has continued and will continue to shape our world. With organizations like Cummins at the helm, advancements in diesel technology will undoubtedly propel us all in

Advanced diesel engines are some of the most fuel and energy-efficient options in the market, but those are just the beginning of their advantages. Some of their advantages are emotional. For a hundred years, people have been firing up a diesel engine to start their work day. But the environmental impact of that economy is now under increasing regulations. Innovative aftertreatment systems and cut

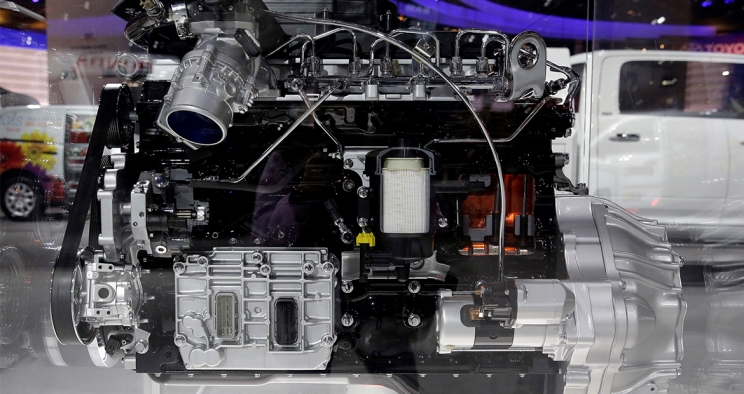

Today, Cummins Inc. announced it will showcase the next generation of integrated powertrain and digital connectivity at the American Trucking Associations' Technology & Maintenance Council's annual meeting and transportation exhibition. This marks the first time that leading fleet professionals from across North America will see a fully-integrated Cummins powertrain: engine, transmission, axle

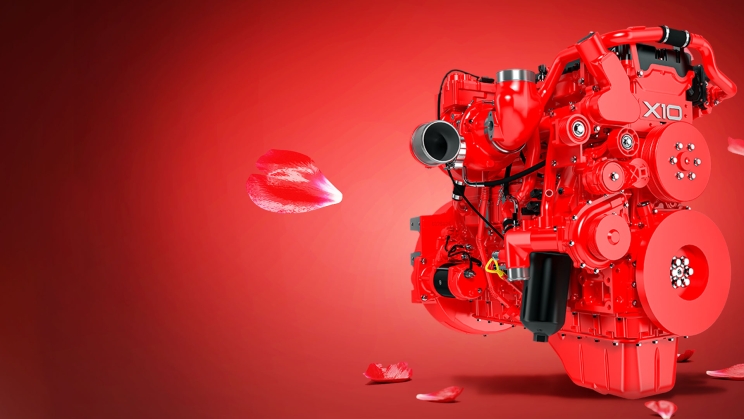

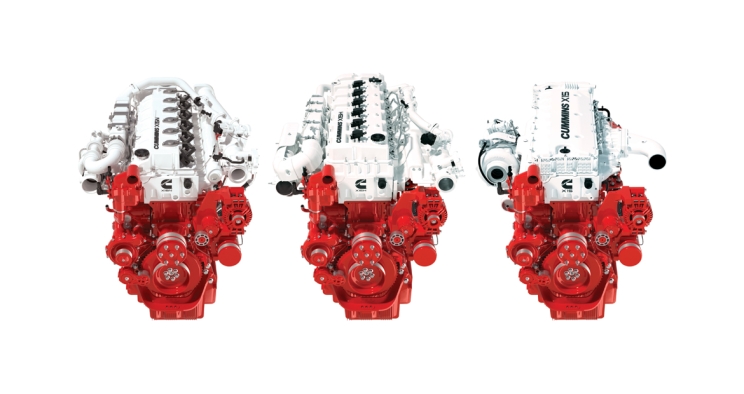

Today, Cummins Inc. (NYSE: CMI) announced it will launch the next engine in the fuel-agnostic series, the X10, in North America in 2026. This engine, named as part of the X engine family, is uniquely positioned to replace both the L9 and the X12 with the versatility to serve both medium and heavy-duty applications. It will be compliant with U.S. EPA's 2027 regulations a full year early. The diesel

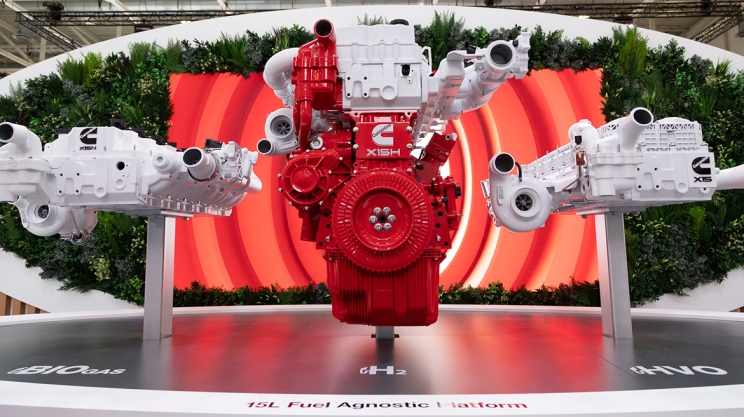

Cummins Inc. (NYSE: CMI) at the IAA Transportation exhibition showcased the new fuel-agnostic X Series platform with hydrogen, biogas and advanced diesel engines offering low-to-zero carbon fuel capability. The next generation 15-litre and 10-litre displacement X Series is designed to accelerate the decarbonization of heavy-duty, long-haul truck fleets while able to meet proposed ultra-low emissio

The first phases of greenhouse gas regulations for commercial vehicles focused on tailpipe emissions, and this perspective brought the industry many efficiency improvements. With the advent of low to zero carbon fuels and new power sources, differences in GHG emissions are becoming more difficult to assess. One example is battery electric powertrains which get their energy from charging via the el

Today, Cummins Inc. (NYSE: CMI) debuted its 15-liter hydrogen engine at ACT Expo in Long Beach, California. This engine is built on Cummins' new fuel-agnostic platform, where below the head gasket each fuel type's engine has largely similar components, and above the head gasket, each has different components for different fuel types. This version, with expected full production in 2027, pairs with

Commercial vehicle fleet managers face a dizzying array of options when it is time to replace or upgrade vehicles. One question that fleet managers often ask is whether there are any good fuel options available to their business besides diesel or gasoline. Alternative fuels, including natural gas, have grown in popularity in recent years due to their broad appeal. Considering a full or partial swi

From tractor trailers and transit buses to delivery trucks and terminal tractors, fleets have traditionally relied on diesel engines to provide the torque, reliability and durability needed by heavy-duty commercial applications. Natural gas engines, however, have emerged as a great alternative to diesel. Drivers, mechanics, and fleet managers appreciate natural gas engines for a variety of reasons

When it comes to natural gas engines, there are a range of frequently asked questions about the cost, practicality, and feasibility of integrating natural gas into commercial fleets. There are certainly preparations that need to be considered, but the learning curve to implement natural gas engines is not as steep as people may think, especially in comparison to the benefits of natural gas in tran

Regulations limiting greenhouse gas emissions (GHGs) from motor vehicles are tightening around the world. With this, both hydrogen engines and hydrogen fuel cells are receiving an increasing interest. Given medium and heavy-duty trucks are a major source of CO2 emissions, the transportation sector's journey to destination zero features both technologies. As more truck makers join the

How can hydrogen fuel power a vehicle? Using hydrogen to power an engine or motor is more straight forward than you might think. There are two ways to do this. The first way involves a device known as a fuel cell. The fuel cell converts hydrogen to electricity, which then powers the vehicle's electric motors, just like in any electric vehicle. The other way is hydrog

The stone age did not end because the world ran out of stones, and the oil age will not end because we run out of oil1. Instead the oil age will end as we (communities, companies, and governments) speed up the energy transition towards our final destination: 100% renewable energy. In this energy transition journey there are giant steps we all celebrate, such as the increased use of green

Plant Location: Whitakers, North Carolina Year opened: 1981 (the first engine was produced and shipped in 1983) Plant size: 1.2 million square feet Business Unit: Engine Business Unit Plant manager: John Judd Employee count: 1,800 Products: On-highway (automotive) and off-highway diesel engines (65-600 brake horsepower) Customers: RMEP has more than 530 customers, including: Daimler, Freigh

In a historic industry move, Cummins Inc., the world's largest manufacturer of diesel engines, (NYSE:CMI) now officially endorses and recommends two Power Service products - Diesel Kleen +Cetane Boost and Diesel Fuel Supplement +Cetane Boost - for use in diesel engines. The announcement comes after significant internal testing concluded both products meet Cummins® requirements, becoming

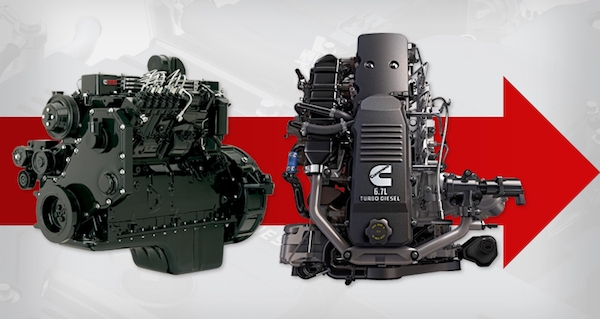

The Cummins 5.9L inline 6-cylinder was a fan favorite in RAM pickups for years, and when it evolved into the 6.7L Turbo Diesel mid year of 2007, a variety of enhancements - along with greater displacement - made it a real crowd pleaser. RAM owners gained a lot more power, improved fuel efficiency and a quieter, cleaner-running engine Through the years, Cummins has promoted higher power density

Late last year, Cummins shipped its first QSK95 built specifically for rail. The engine - one of the most powerful high-speed diesels ever used in commercial rail - was delivered to a Siemens manufacturing facility in Sacramento, destined for duty in U.S. passenger rail. Capable of top speeds of 125 mph when used as the primary power of a locomotive, the engine delivers 4,400 hp, more than any