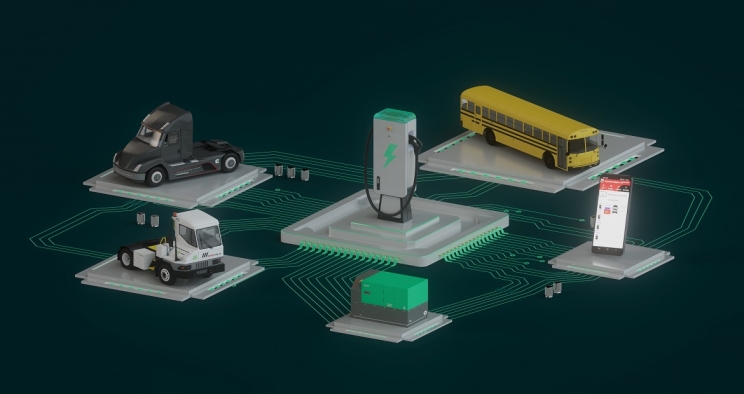

Welcome to the era of smarter, cleaner power

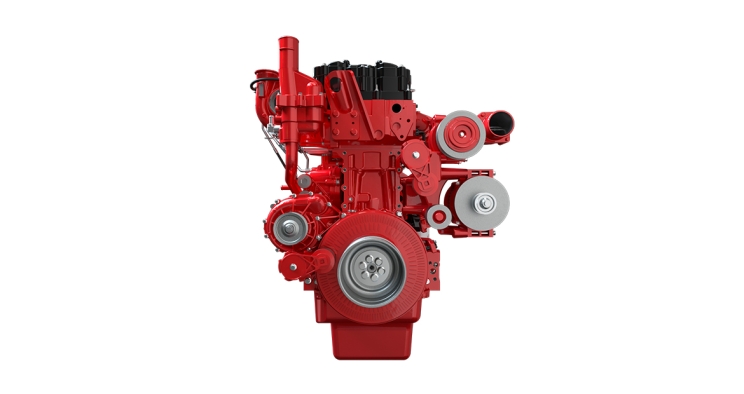

The innovative architecture of the X12 results in a remarkably low engine weight, at only 2,050 lb. A sculptured block design allows unnecessary mass to be removed while retaining high rigidity. Substantial weight savings are also achieved by the use of high-strength composite materials for the oil pan and valve cover. "During the design process for the X12, we evaluated every opportunity to re

Cummins released its water conservation goal in 2014 as part of its 2020 Environmental Sustainability Plan, pledging to reduce water use intensity by 33 percent, adjusted by labor hours. As of the third quarter of 2016, the company's water efficiency efforts had resulted in a 42 percent intensity reduction or 18 percent on an absolute basis. Because the Company achieved the initial goal ahead

Cummins will hold ride-and-drives at MATS on March 23, 24 and 25, with the latest 2017 X15 Efficiency Series and X15 Performance Series engines hauling fully loaded trailers on an interstate loop. Drivers will get a real-world feel for the smooth acceleration, tremendous pulling power and exceptional fuel efficiency that Cummins X15 engines deliver - with zero compromises. Reservations for specifi

"Cummins announced our new MidRange engine platforms last year, but we haven't been resting on our laurels. We constantly strive to make our products better for our customers, so they can keep their truck on the road longer, getting the job done. Cummins is a company committed to innovation, and in 2017, the market leader keeps getting better," said Jeff Caldwell, Executive Director of North Ameri

"Cummins 100-year history is defined by our diesel technology leadership. As we have seen with the latest Stage V engines, these products will continue to develop and be lighter, more powerful and more efficient. Approaching our second century, we see alternative power as a complement to diesel. We call it energy diversity, providing a range of powertrain solutions for customers: clean diesel, ren

"Cummins Tier 4 Final engines were first shown at the last CONEXPO three years ago. To complete 640 successful customer installations since then is a major achievement by our engineering team, and highlights our capability in this area. We invested heavily in our products and our application support work with our OEMs around the world, not just in North America and Europe, but also in South Korea,

"These new products are powered by Cummins QSJ5.9G engine, which is based on the legendary Cummins 6B5.9 engine, using spark-ignited lean-burn technology. It meets exhaust emissions requirements without the need for aftertreatment," said Mark Westphal, Technical Project Leader. The generators come with a wide range of features, including the Cummins user-friendly PowerCommand® 1.1 control, whic

Cummins Guidanz™ - a new free mobile app operating through a Wi-Fi or a cellular connection - allows customers to quickly read engine fault codes on Tier 3 and later engines when paired with the new Bluetooth®-enabled INLINE™ mini-Vehicle Data Link Adapter, or INLINE 7 using Bluetooth mode. The Guidanz mobile app can be downloaded from the Apple® App Store® or Android's® Google Play™ for use on Ap

"Although the Stage V regulations do not directly affect North America, Cummins technology leadership enables us to offer significant product and technology enhancements to construction equipment manufacturers for 2019. This next generation of products will appeal to every OEM looking for significantly improved performance with lower installed costs for Tier 4 Final, as well as those needing a sim

"As a result of the creation of the Power Systems business segment last year, we re-evaluated how we wished to be positioned in the market. Coming together under one new business structure means that the time is right to move to a more cohesive brand strategy under the one Cummins brand, one that will better position us to leverage our brand strength and ensure that we continue to deliver on our b

The L9 builds on the ISL9's legacy of providing a robust, durable solution for motorcoach customers. Compared with the ISL9 from a decade ago, customers can expect to see as much as a 15 percent fuel economy improvement using the 2017 L9-powered motorcoaches. Contributing to the fuel-economy improvement is the use of the new Single Module™ aftertreatment, which is displayed in the Cummins booth. T

The X12 utilizes the new Single Module™ aftertreatment system, which takes up to 60 percent less space and weighs up to 40 percent less than prior aftertreatment configurations. Combined engine and aftertreatment weight for the X12 is around 2,340 lb - significantly lower than that of any other heavy-duty engine. Rigorous testing in the most challenging operating environments around the world h

The results were proven through extensive collaborative development efforts, covering millions of miles of real-world truck testing. In an analysis of cost savings potential, comparing the use of conventional oil and synthetic blend CK-4 oils in the Cummins X15 engine, Valvoline Premium Blue 15W-40 was proven to save upwards of $20,000 in annual oil maintenance cost and productivity savings for a

The new mobile app reduces the need to drive to a certified service location or wait for a technician to arrive on site. Customers can view prioritized engine faults using the Guidanz mobile app paired with an INLINE™ mini Bluetooth® adapter, which provides critical information they can quickly share with their operations manager or service provider. By either emailing the operations manager direc

Isolating and interpreting key engine and aftertreatment data every day, Connected Advisor provides customers with prioritized, time-based recommendations to distinguish between immediate repair needs and those that can be scheduled a few days out. Fault reports, including probable causes and recommended actions, are sent to fleet managers daily to help initiate the repair process. For faults requ

For years, recommended oil drain intervals have been based on a set distance and/or time period. Vehicles carrying heavy loads, running across rugged terrain or having a high percentage of idle time were treated the same as those with less strenuous duty cycles. The Cummins OilGuard program allows participating fleets and owner-operators to safely extend oil change intervals while keeping full war

For the first time in the North American agriculture market, Cummins debuts the next generation of ultra-clean engines, which will be available beginning in 2019. Designed to meet European Union (EU) Stage V emissions regulations, they offer distinct advantages to North American manufacturers. Visitors to the Cummins booth (M6/M8) will see multiple Tier 4 Final power solutions. As many customer