Driving toward cleaner air: Innovations in aftertreatment for regulation compliance

By Cummins Components Business Unit

Emission regulations have become crucial in reducing the environmental impact of heavy-duty vehicles. The implementation of U.S. Environment Protection Agency’s (EPA) 2027 emission standards in North America is expected to be a significant milestone in this ongoing endeavor, drastically lowering nitrogen oxide (NOx) emission limits by over 80%. The standards also dictate the extension of the emissions useful life (EUL) of vehicle components to ensure sustained compliance and performance. Today's NOx and EUL requirements have remained unchanged for over a decade, presenting new and significant challenges to an industry accustomed to established standards. Addressing EPA27 regulations will require a system-level approach, integrating both the engine and aftertreatment systems, with careful optimization between the two. This article will explore two potential solutions.

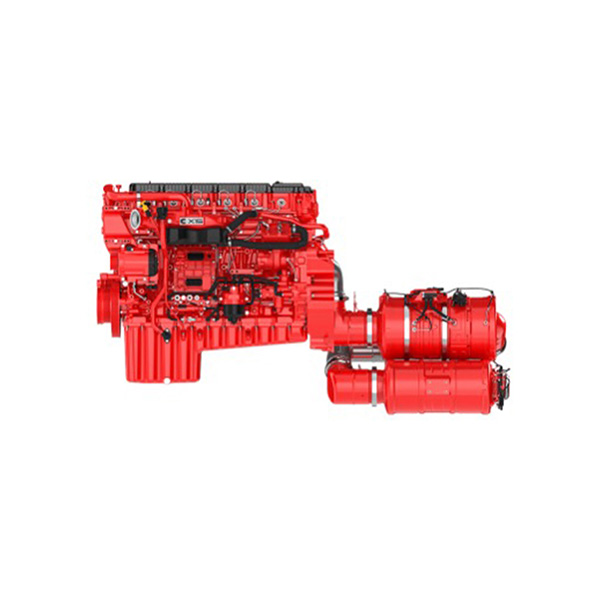

System trade-offs significantly influence design choices for both the engine and aftertreatment, as these components must work in tandem to ensure optimal performance, serviceability and configurability for customers. Since 2007, Cummins Inc.'s Engine Business has partnered with Cummins Emission Solutions (CES) to develop system designs in North America that meet EPA regulations while prioritizing customer needs. The 2027 product lineup will introduce a new aftertreatment architecture, the Twin Module, built on proven solutions and adaptable configurations that minimize impact on customer chassis. When paired with the EPA 2027 X15 engine, which retains cooled Exhaust Gas Recirculation (EGR) and in-cylinder hydrocarbon dosing, the Twin Module is powered by a 48V alternator that enables the CES-designed electric heating system. This integration, featuring a belt-driven alternator and the application of electric heat in the aftertreatment, allows the 2027 solutions to meet lower emissions requirements without compromising engine performance or durability. As with the current Single Module system, the Twin Module continues CES's commitment to ease of serviceability and customer configurability.

CES Electric Heating System to Meet EPA27

According to Bethany Huckaby, Product Manager - CES, her team "is focused on the best way to apply appropriate technologies for the combination of critical factors: what does the regulation demand, what does the engine need and what does the market require." For the EPA27 regulations in North American On-Highway markets, the system will utilize electric heat - along with other design changes - to deliver emissions performance in a "future proof" manner. This approach allows the EPA 2027 engines to concentrate on their performance without the added concern of thermal management required for aftertreatment.

Leveraging the advantages of electric heating technology makes sense in North America's On-Highway space for several reasons. By developing its own electric heaters specifically designed for heavy-duty commercial environments, CES is equipping customers with scalable solutions for the future. The Twin Module systems can apply heat to the exhaust "on-demand" and precisely where needed, ensuring accurate thermal management without compromising engine performance. This leads to improved engine efficiency-and consequently better fuel economy-across all potential operating conditions that a truck may face in North America. If future regulations continue to tighten emissions standards, the system architecture is already prepared to meet those requirements with minimal space claim adjustments, preventing customers from needing to redesign their chassis entirely.

Much like the earlier aftertreatment products, the Twin Module is designed to offer a comprehensive range of configuration options for customers. Utilizing electric heaters reduces the additional catalyst volume required resulting in a more compact system, and the assemblies can be arranged in several ways through a host of configurable product options. CES recognizes that maximizing flexibility in vehicle integration is crucial as the EPA27 regulations demand enhanced performance for longer durations than ever before.

CES Technologies for Euro 7

Another example of a CES solution that balances regulatory demands with engine and market needs can be found in Europe, where the implementation of Euro 7 emission regulations will begin in 2027. While these new regulations are less stringent than EPA 2027, they still require significant reductions in NOx and particulate number (PN) compared to Euro 6 levels. Additionally, Europe has introduced legislation specifically aimed at reducing CO2 emissions across fleets. The Vehicle Energy Consumption Calculation Tool (VECTO) mandates that original equipment manufacturers (OEMs) offer a broader range of powertrain solutions, enabling fleets to achieve a mandated percentage reduction in CO2 emissions (at the vehicle level) compared to a 2019 baseline. The target for 2025 is a 15% reduction in CO2 at the vehicle level. The 2030 target was recently revised from 30% to 45%, posing a significant challenge given the current infrastructure's readiness to support battery electric vehicles (BEV), hydrogen internal combustion engines (H2 ICE), and hydrogen fuel cells (HC FC) in the heavy-duty market. Meeting both Euro 7 limits and VECTO requirements is a considerable undertaking, requiring vehicle manufacturers to offer a variety of powertrain solutions, including a mix of clean diesel, hybrid, BEV and H2 ICE technologies.

Cummins Emission Solutions supports OEMs in their path to cleaner diesel solutions with a robust portfolio of components, including DEF and hydrocarbon dosing systems, mixers, e-heaters, and DEF filters. For North America, EPA27 poses an exciting opportunity to leverage existing technologies while incorporating the CES electric heating system. The European market is also expected to generate a huge demand for innovative aftertreatment solutions driven by the Euro 7 regulations. CES continues to assess its options for Euro 7 solutions while actively collaborating with major OEMs to provide reliable, high-quality components that support their individual needs. As global emissions regulations become increasingly stringent, Cummins is well-prepared to address these unprecedented challenges with solutions that meet the diverse demands of different markets and customers.

Author Profiles

Related Tags