Digging Deeper: What will be the mining industry’s key priority in the decade ahead?

By Aytek Yuksel, Content Marketing Leader - Power Systems

It was not surprising that Fred from The Flintstones was a miner, given mining is one of the oldest industries in the world. The famously pink colored salt you used for dinner last night to bring out the flavors comes from the Khewra salt mine, which dates back to the era of Alexander the Great and is still in operation today.

While the mining industry dates back to ancient times, and Cummins has been a part of this journey since the Cummins Model F engines powered the very first diesel shovel in 1926, today it is rapidly modernizing.

“The mining industry is now an innovation hub where mine sites feature the latest technologies from remote control equipment to driverless (autonomous) trucks. In fact, two of the world’s five largest mining companies were recently featured on The Most Innovative Companies 2019 list,” said Beau Lintereur, Executive Director - Power Systems Aftermarket and Global Mining Markets at Cummins. “Going forward, miners will be increasingly leveraging these and other innovations with a key goal in their minds: sustainable lowest cost of production.”

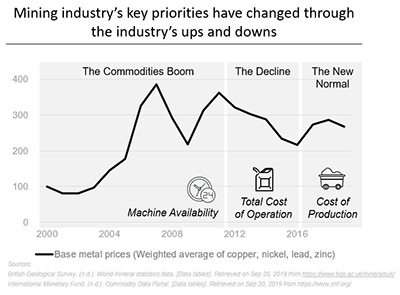

Before diving into sustainable lowest cost of production, let’s look at how the mining industry’s key priorities have changed through the industry’s ups and downs.

Commodities Boom: 2010 and 2011 were remarkable years where the mining industry had increased the amount of basic metals and iron ore mined by 15% each year; the fastest pace in our recent history. The key priority for the mining industry during this era was machine availability. This refers to the time duration the equipment was ready to work when it mattered. The cost of running the equipment did matter, but the priority was having the equipment available to generate revenue.

Commodities Boom: 2010 and 2011 were remarkable years where the mining industry had increased the amount of basic metals and iron ore mined by 15% each year; the fastest pace in our recent history. The key priority for the mining industry during this era was machine availability. This refers to the time duration the equipment was ready to work when it mattered. The cost of running the equipment did matter, but the priority was having the equipment available to generate revenue.- The Decline: The commodities boom came to a screeching end in 2013 with mineral and ore prices plummeting. The key priority for the mining industry quickly shifted from availability to total cost of ownership (TCO). It was all about the cost of fuel, repairs, maintenance and others. The bottom of this cycle was in 2016 and several players within the mining industry found themselves focused on the immediate cost of survival, where the emphasis was investing on aspects of the business directly linked to the short-term survival of the company.

- The New Normal: As the industry has emerged from the decline and the commodity prices started to stabilize, an adjacent development was also taking place; the rise of advanced analytics. The mining industry took full advantage of advancing analytics and associated technologies, and has rapidly pivoted its priority towards the lowest cost of production (COP). COP brings together TCO and the amount of production achieved, and is a more comprehensive look at mining operations.

Sustainable lowest COP will be the key priority for the mining industry in the decades ahead

COP helps the mining industry optimize its operations with a balanced focus on cost and production, and was a great starting point for the industry coming out of the decline. Going forward, sustainable lowest COP will be the next step for the mining industry, driven by two explanations:

- Social license to operate: Communities, employees and shareholders put increasing scrutiny to companies’ business practices regarding sustainability. While this is not limited to mining, the growing momentum behind social license is to amplify the importance of sustainable lowest COP.

- Risk management: Risk within mining operations is far beyond financial risks and could include fatalities and irreversible damage to the environment. With so much at stake, miners are expected to improve their already advanced risk management procedures. This strive for progress will increase the importance of adding sustainability to COP.

Let’s take a look at two examples on how sustainability and COP come together.

No. 1: Today’s engines are cleaner and more powerful than their predecessors

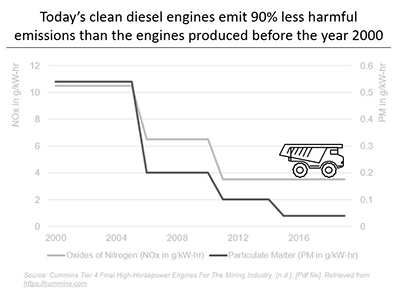

Today, a typical Cummins engine used in a mining application emits 90% less particulate matter (PM), oxides of nitrogen (NOx) and hydrocarbons (HC) compared to engines produced before the year 2000. Less NOx means less smog, and less particulate matter means less accumulation of these particles on ground or water.

Today, a typical Cummins engine used in a mining application emits 90% less particulate matter (PM), oxides of nitrogen (NOx) and hydrocarbons (HC) compared to engines produced before the year 2000. Less NOx means less smog, and less particulate matter means less accumulation of these particles on ground or water.

It is especially important to pay attention to PM since mining sites tend to be in rural areas in close proximity to lakes and forests, where extensive accumulation of PM could affect the diversity of the ecosystem.

Today’s engines also offer more power compared to their older versions, delivering improved productivity for miners while reducing the harmful emissions.

No. 2: Improved fuel efficiency delivers better financial performance and lowers the carbon footprint

Fuel is estimated to be one third of the total cost mining companies incur in operating their equipment. Combine this with higher fuel efficiency that reduces emission of greenhouse gases such as carbon dioxide, and you have a winner.

Keeping energy costs down while protecting the environment is critical for the industry and Cummins. The newest Cummins Tier 4 Final engines (over 751 horsepower) offer up to 3%to 5% better fuel efficiency than Tier 2 engines with no compromise to engine power and reliability. This fuel efficiency gain was achieved through a combination of in-cylinder improvements and the use of Cummins Selective Catalytic Reduction aftertreatment technology, which is used by over 400,000 engines around the world.

Sustainable lowest COP does a good job bringing together two key priorities: sustainability and economics. Cummins will continue to bring new technologies ranging from advanced analytics to various powertrain solutions to help the industry advance in sustainable lowest COP.

To learn more about trends in the mining industry follow us on Facebook and LinkedIn. To learn more about mining power solutions Cummins offers, visit our webpage. To learn more about how Cummins is powering a world that’s “Always On,” visit our web page.

Author Profiles

Aytek Yuksel, Content Marketing Leader - Power Systems

Aytek is a marketing leader at Cummins, focusing on technology and thought leadership. Since joining in 2008, he has held various marketing roles and now shares insights on markets, technologies, and energy transition. Aytek lives in Minneapolis with his wife and two kids.

Related Tags