An aftertreatment system that meets the future EPA regulations

By Cummins Inc., Global Power Technology Leader

What are the upcoming emission regulations in North America?

The EPA27 emissions rule is a set of regulations established by the Environmental Protection Agency (EPA) to significantly lower nitrogen oxide (NOx) emissions from light-, medium- and heavy-duty vehicles. These regulations take effect with the 2027 engine models and require a reduction in NOx emissions by more than 75% compared to current standards.

Complying with these stringent standards requires a system-level approach that optimizes both the engine and aftertreatment components. This ensures vehicles meet emissions requirements while maintaining fuel efficiency and performance in real-world operating conditions.

How has the aftertreatment system changed to meet EPA27 regulations?

To achieve compliance with EPA27, Cummins has made changes to the aftertreatment system including:

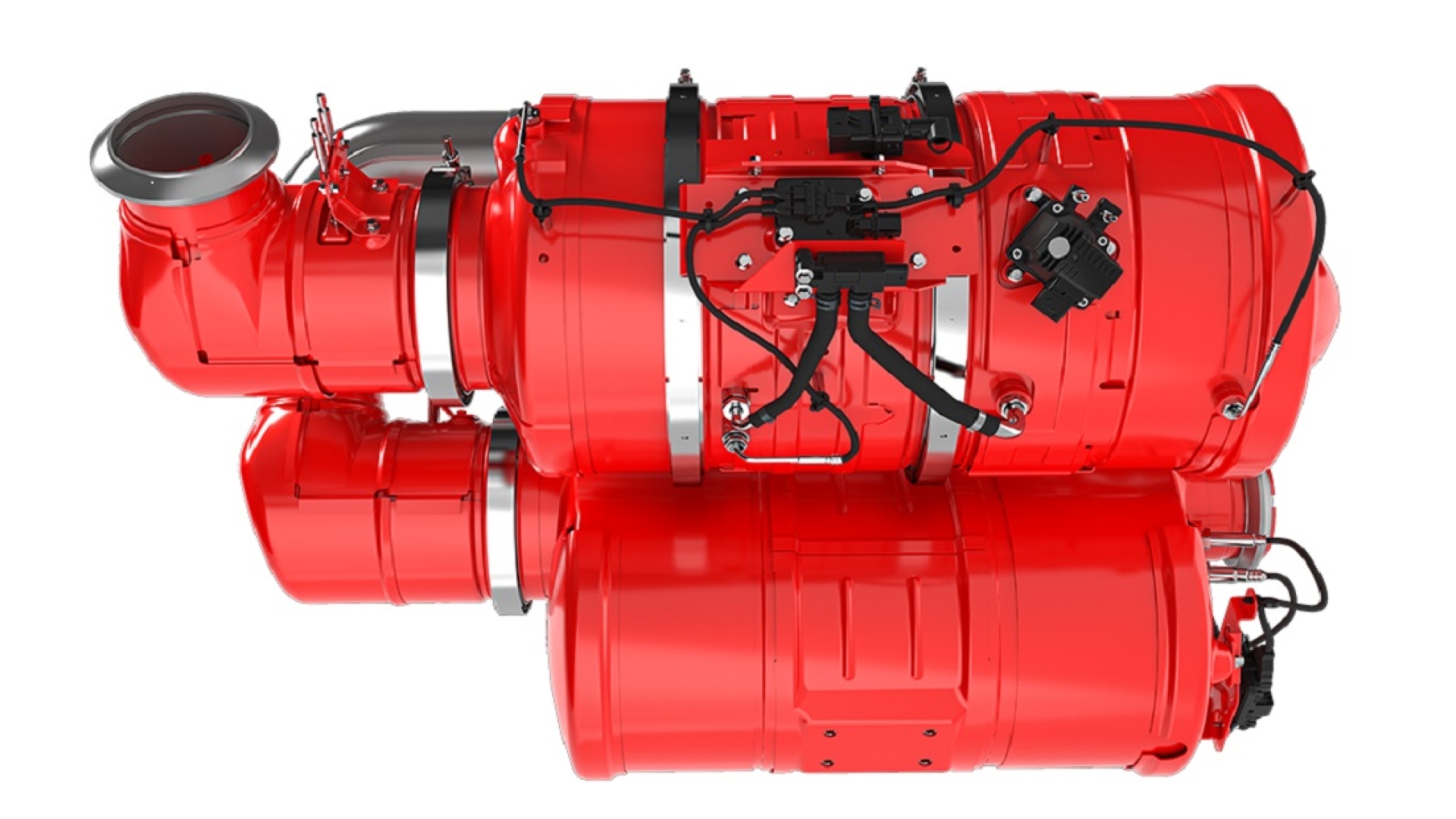

- From Single Module to Twin Module: EPA27 systems will have two catalyst assemblies: a Diesel Particulate Filter (DPF) Assembly and a Selective Catalytic Reduction (SCR) Assembly.

- Cummins Electric Heating System: Two 5kW electric heaters, located at the inlet of each assembly, are powered by a 48V alternator mounted on the engine, allowing for precise temperature control.

- SCR Assembly Design: The SCR Assembly implements a parallel exhaust flow to improve backpressure and overall length while minimizing heat loss.

By implementing these design changes, Cummins improves emissions performance while maintaining durability and reliability.

Why are electric heaters the solution to meet EPA27 rules?

For NOx reduction technologies like SCR catalysts to be effective, they must reach and maintain optimal operating temperatures. However, cold engine start-ups and low-load conditions can prevent catalysts from heating up quickly enough to reduce NOx, leading to higher emissions.

Electric heaters provide a direct solution by supplying heat exactly when and where it is needed. By quickly bringing the catalysts up to the required temperatures, the system begins reducing emissions almost immediately. This ensures compliance in real-world conditions, even during the most challenging operations.

Beyond temperature management, another key benefit of electric heaters is the ability to reduce overall system size. Instead of significantly increasing the catalyst volume to meet emissions limits, the Twin Module system strategically uses heat to optimize performance. Even though the NOx reduction requirements are over 75% stricter, the Twin Module catalyst volume is less than 20% larger than the Single Module equivalent in current products. Thanks to improvements on the 2027 X15, the engine's weight has been sufficiently reduced, making the overall engine and aftertreatment system weight-neutral compared to the previous X15 system.

Why has Cummins Emission Solutions developed its own electric heaters?

Cummins Emission Solutions explored available electric heaters in the commercial industry but found that none met its high standards for durability, power, and performance. As a result, the CES team designed its own heating solution tailored to the demands of providing an EPA27-compliant aftertreatment system.

These heaters are engineered for long-term reliability, ensuring minimal impact on exhaust flow while delivering the necessary heat for catalyst activation. While there is no scheduled maintenance for the heaters, they are designed to be serviceable in case of failure. This minimizes vehicle downtime and helps operators return to the road quickly.

Conclusion

Cummins has leveraged its experience in emissions control by combining established technologies like DOC, DPF, and SCR catalyst architecture with a new cutting-edge electric heating solution. This innovative approach ensures compliance with the EPA27 rule while maintaining efficiency and reliability. By optimizing heat management and system performance, Cummins delivers a robust solution that meets the evolving needs of the commercial vehicle industry.

Author Profiles

Cummins Inc., Global Power Technology Leader

Cummins Inc., a global power solutions leader, comprises five business segments - Components, Engine, Distribution, Power Systems, and Accelera by Cummins - supported by its global manufacturing and extensive service and support network, skilled workforce and vast technological expertise. Cummins is committed to its Destination Zero strategy - the company's commitment to sustainability and helping its customers successfully navigate the energy transition with its broad portfolio of products. Cummins has approximately 69,900 employees and earned $3.9 billion on sales of $34.1 billion in 2024. See how Cummins is leading the world toward a future of smarter, cleaner power at www.cummins.com.

Temas relacionados

Related Tags