How Cummins ReCon® products can help your sustainability goals

By Cummins Inc., Global Power Technology Leader

As part of its Planet 2050 environmental sustainability strategy, one of Cummins Inc.'s goals is to create a circular lifecycle plan for every part to use less, use better and use again. The lifecycle plan for parts considers the reduction of remanufacturing waste, designing high-value components to have sufficient life for multiple use cycles, and planning for material recycling.

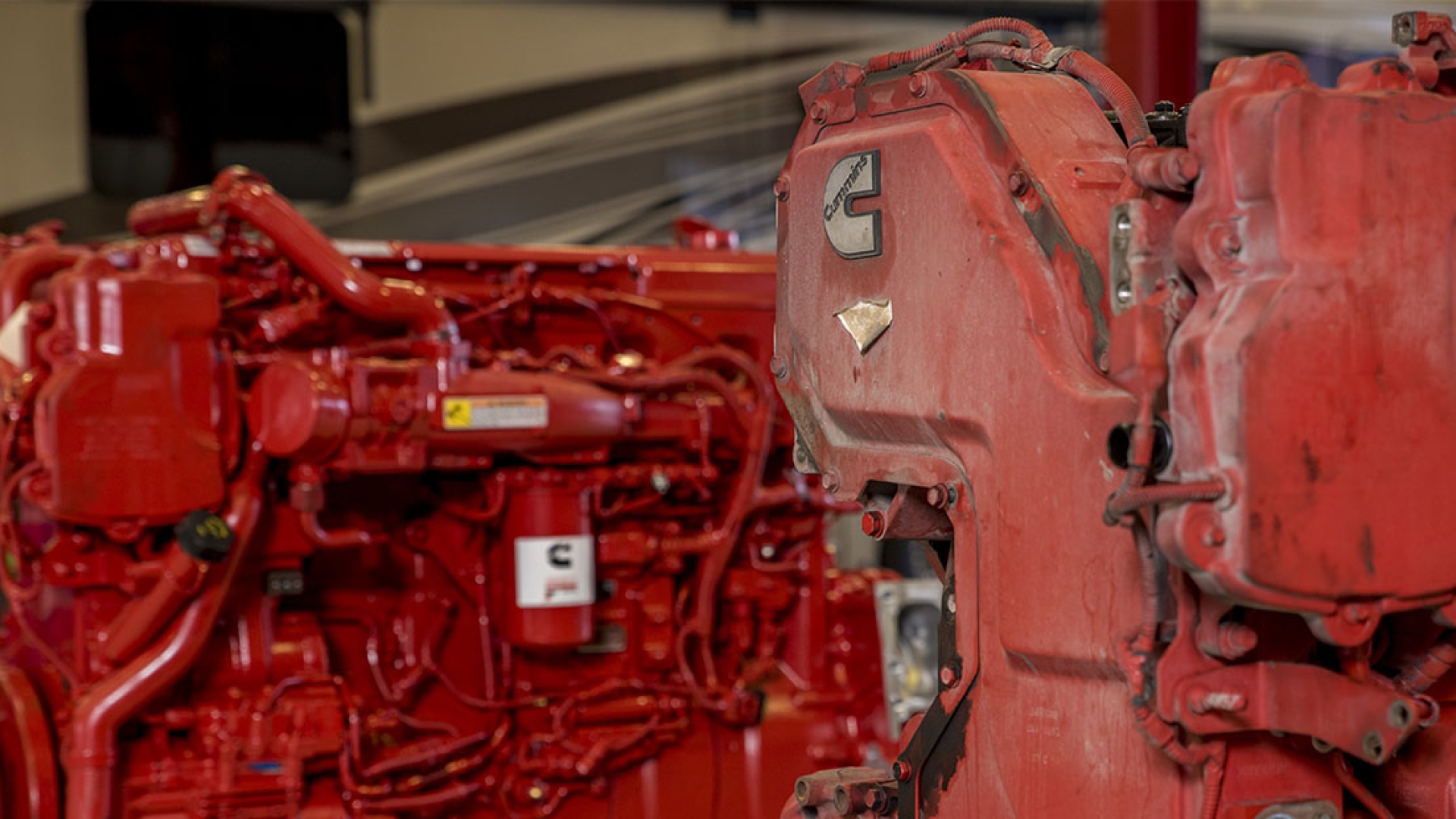

Cummins ReCon® products give customers the choice to replace parts with remanufactured parts or purchase ReCon engines. ReCon engines are a very sustainable choice, using up to 85 percent less energy to produce than a new engine.

This article explores the considerations for remanufacturing and ways in which Cummins ReCon can help you towards your sustainability goals.

Cummins' approach to remanufacturing

- Design and validation of technology with remanufacturing in mind: Sustainability is built into Cummins' engines and parts beginning at the design phase. From the outset, Cummins parts and components are designed with the environment and remanufacturing in mind. For instance, remanufacturing process uses sustainable coatings that limit negative environmental impacts. Cummins ReCon engines and parts are designed in a way that minimizes hot testing, which can significantly reduce the energy used and the carbon emissions from the production process. Remanufacturing methods and tools are also validated to ensure that all Cummins ReCon products will perform as expected, meet all environmental regulations, and achieve sustainability goals.

Up to 85 percent of an engine can be remanufactured, and Cummins engines are built to be remanufactured multiple times. Engines are designed to facilitate maintenance and remanufacturing processes such as disassembly, cleaning, and restoration. This means a reduced amount of energy, natural resources and material is required to deliver a like-new engine to the customer at an optimal price, potentially saving thousands of dollars.

-

Reducing material waste throughout the process: Remanufacturing engines eliminates the need to forge new parts, saving metal ore, energy, and carbon emissions. Even compared to recycling the metal parts, remanufacturing results in less material loss, due to the losses associated with reforging steel, not to mention the reduction of energy use and carbon emissions.

Cummins is also committed to collaborating with sustainable partners and driving change throughout the supply chain to promote resource conservation and circular economy models. In addition, Cummins ReCon uses recycled materials, and is always working to find ways to incorporate renewable resources into factory and equipment design.

- ReCon parts help maintain engine life: Cummins provides remanufactured parts such as electronic control modules (ECMs), fuel injectors, compressors, turbochargers and more. These parts are cleaned, inspected, remanufactured and tested to meet or exceed all original factory requirements. Using Cummins ReCon parts can help maintain the longevity of a Cummins engine. It also offers a sustainable approach by making use of remanufactured parts instead of always relying on new ones.

-

Remanufactured engines in use and disposal: A Cummins ReCon engine is an engine that has been completely disassembled, inspected, cleaned, tested, painted and brought back to "like new" condition in a Cummins remanufacturing facility. These newly built engines come with the latest ReCon or new parts, warranty and have zero hours/miles. A great benefit of Cummins remanufacturing is that you can get money back in exchange for your worn-out engine or part. Any Cummins-authorized repair facility worldwide will accept your old part, perform a simple external visual inspection and give you immediate credit toward its replacement. The part just needs to be in off-engine condition to qualify for core acceptance and reimbursement.

-

Increasing efficiency and reducing waste through advanced technologies: Cummins has developed and implemented initiatives to reduce the environmental impact of remanufacturing facilities, including reducing plastic packaging, reusing and cleaning wastewater from processes and reducing machining scrap. Cummins has made significant investments in remanufacturing facilities in recent years to ensure that all customers can choose sustainable and reliable products to meet their needs.

Cummins ReCon facilities utilize technologies like collaborative robots, delivery robots, and laser cleaning, all aimed at enhancing workplace safety and efficiency. Leveraging these advanced technologies demonstrate Cummins' commitment to innovation. Metal additive manufacturing, also known as 3D printing, is a technology that Cummins is adopting to further its sustainability efforts. Cummins sees 3D printing as a key manufacturing process so when suppliers stop producing certain parts, printed versions can serve as replacements, prolonging product lifecycles. Metal 3D printing is a near-net-shape process, resulting in reduced material waste and fewer processing steps. Additionally, this technology promotes local production, cutting down on transportation implications and readily allowing for engineering and performance updates. This localization not only benefits the environment but also streamlines the supply chain.

Cummins ReCon is a promise of continuous environmental stewardship, from creation to remanufacturing. For more information on how Cummins ReCon can help meet your sustainability goals, contact your local Cummins distributor or authorized Cummins dealer location.

Author Profiles

Cummins Inc., Global Power Technology Leader

Cummins Inc., a global power solutions leader, comprises five business segments - Components, Engine, Distribution, Power Systems, and Accelera by Cummins - supported by its global manufacturing and extensive service and support network, skilled workforce and vast technological expertise. Cummins is committed to its Destination Zero strategy - the company's commitment to sustainability and helping its customers successfully navigate the energy transition with its broad portfolio of products. Cummins has approximately 69,900 employees and earned $3.9 billion on sales of $34.1 billion in 2024. See how Cummins is leading the world toward a future of smarter, cleaner power at www.cummins.com.

Temas relacionados

Related Tags