Sustaining continuous innovation

Cummins inventors go the distance to positively impact our world

By Tamra Knudsen, Brand Journalist

With a distinguished history as the world's largest independent manufacturer of power solutions, there is no doubt Cummins Inc. is known for its continuous innovation. How has continuous innovation been non-stop at Cummins for over a century? Through the efforts of forward looking, problem-solving employees making it their purpose to improve existing products, work diligently to create new ones and stay in tune to their customers, delivering what's needed to make the world a more prosperous place.

Since Clessie Cummins' first two patents awarded in 1921, Cummins engineers have continued to foster invention and innovation year after year. As a matter of fact, Cummins' very own Chair and CEO, Jennifer Rumsey, started as an engineer in the company 25 years ago and holds multiple patents with four assigned to Cummins.

Encouraging innovation

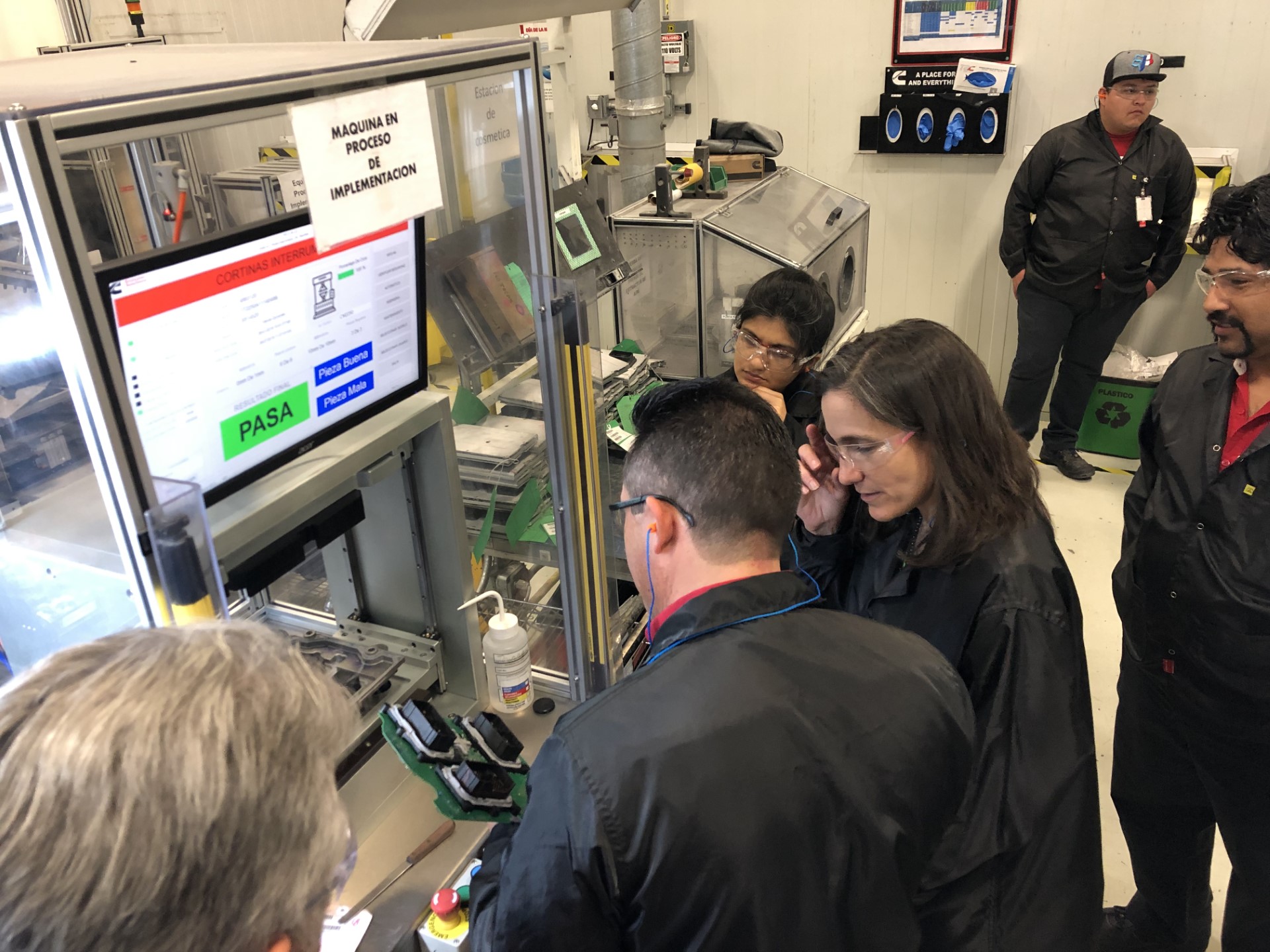

Joan Wills, Executive Director, Software & Electronics Engineering at Cummins, with over 25 years of service, tells us what motivates her to innovate: "I have a passion for problem-solving and have observed three key steps in the process. First, you need to understand the problem and know that it's important to solve. Next, you must have the confidence and support to start working toward finding a solution. And, most essential, when it seems impossible to find the right solution, keep going anyway."

To date, Wills has received an impressive 26 patents during her tenure at Cummins and is the first female recipient of the prestigious Dr. Julius P. Perr Innovation Award. Now in its 23rd year, the annual award recognizes employees demonstrating excellence in innovation and technology who develop significant intellectual property for Cummins products. Since 2000, only 84 patents have been selected, with each invention having the criteria of adding value to the Cummins brand promise of innovation and dependability.

"Throughout my earlier career, I delivered different solutions to problems," Wills continues. "I failed many times along the way but kept coming up with inventions that addressed some of Cummins' key emission reduction challenges for diesel engines. That inspires and gives me confidence to keep working toward solutions. Now I'm thankful to be in a position to support others who find something they care about, encourage their hard work in resolving issues, and, in time, witness their positive impact in the world."

Investing in the ideas

As important as it is to create something new, it's equally important to protect the idea of that creation and its future use. That's where intellectual property (IP) steps in, providing protection through patents, copyrights, trademarks and trade secrets. The IP system aims to foster an environment in which creativity and innovation can flourish while providing vital safeguards.

Cummins invests significant amounts of resources toward innovation, including billions of dollars in research and technology expenses, $1.2 billion in 2022 alone. "We are committed to creating products that are environmentally sustainable," says Jennifer K. Light-Holets, R&T Intellectual Property Manager with 24 years at Cummins and the first female Chair of Cummins' Invention Review Committee (IRC). "It takes employees who are experts in the field of engineering and technology committed to coming up with ideas to improve our products or create new ones for our customers, our world. And we go to great lengths to protect those technologies and brilliant ideas with our intellectual property processes."

How patents protect

Patents protect the interests of the assignee whose technologies are truly groundbreaking and commercially successful by ensuring an assignee can control the commercial use of the invention. Patents also foster technological innovation by providing incentive for research and development.

As an inventor of 38 patents and 27 active patent pending applications, Light-Holets personally knows what it takes to attain a patent and works with her team of IRC members to annually review hundreds of invention disclosures, over 250 in 2022, submitted by Cummins employees in determining: 1) their commercial value or benefit to customers, 2) if they are truly novel, i.e. not described in publicly available literature or used elsewhere in the world, or 3) if they contain patentable material, such as an article to manufacture versus a mathematic formula.

Light-Holets tells us more about the IRC at Cummins: "The committee is comprised of representatives from legal, marketing, engineering and respective subject matter experts. The main job is to review research and technology innovations and other intellectual property to determine which inventions should be filed as patents, kept as trade secrets, or published into the prior art domain to prohibit others from seeking similar patents in the future. Wherever there is a problem solved with a new, unique solution, there is a potential for intellectual property."

Cultivating continuous innovation

"Creating value through diversity, putting different teams together and listening to different ideas from different individuals, while providing adequate infrastructure and resources, that's the key combination and how ideas evolve and lead to solutions," says Wills. "If you can find the right people and resources to leverage and support the efforts, you can change the world. Cummins is doing just that with investing in and creating the newest technologies to transform our industry by reducing carbon and offering the range of products needed to sustain our industry and world."

The possibilities to make positive changes in the world are endless. It's no wonder Cummins employees continue their quest to innovate and bring forth breakthrough technologies to make people's lives better.

Author Profiles

Tamra Knudsen, Brand Journalist

Tamra Knudsen is a Brand Journalist for Cummins with extensive experience in the Capital Goods sector, serving over 20 years in various corporate communications roles. She began her career in accounting, moving into numerous positions within finance, marketing and administration, until she discovered her niche in the field of communications. Her passion is to create transparent and meaningful content that educates, informs and engages readers on a variety of topics for both external and internal audiences. Tamra graduated from the University of Wisconsin, Parkside, with a BS in Business Administration and Management.