Cummins continuing to supply critical filtration material for personal protective equipment

In this Q&A, Amy Davis, Vice President of Cummins Filtration, shares an update on the company's progress to provide filter media to mask manufacturers around the globe.

By Cummins Inc., Global Power Technology Leader

As the world began to grapple with COVID-19, employees at Cummins were working on innovative solutions to help supply PPE that was in high demand. On April 6, Cummins announced plans to use their filter technology to supply critical materials for N95 respirator masks, an essential piece of personal protective equipment for front-line healthcare workers.

Following the N95 announcement, on April 14, Cummins announced an additional partnership with 3M, which would include the utilization of equipment typically used for producing diesel engine filters to manufacture high-efficiency particulate filters for use in 3M’s powered air purifying respirators (PAPRs).

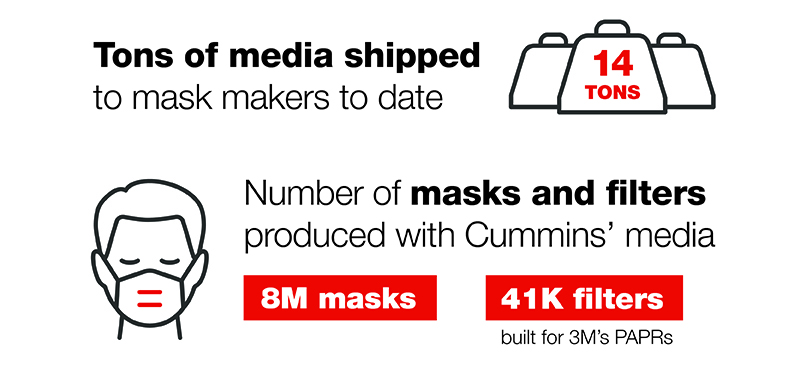

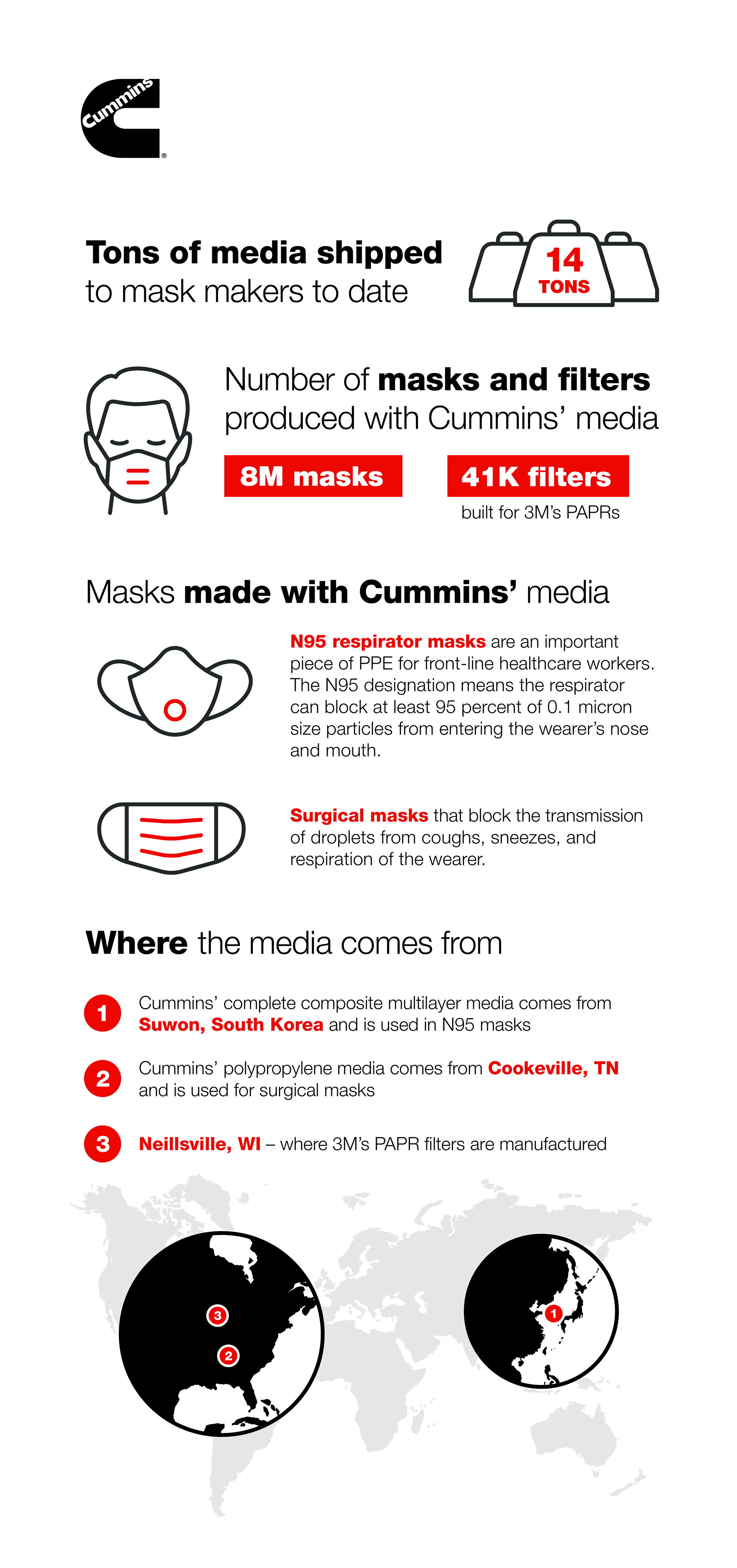

To date, Cummins has provided more than 14 tons of its filtration media to mask manufacturers across the globe, which has been used to produce more than eight million masks. Amy Davis, Vice President of Cummins Filtration, recently shared an update on the company's progress to date.

Q: First, can you share more about the Cummins Filtration business and your core products?

DAVIS: Our core expertise is designing, manufacturing and selling air, fuel, hydraulic and lube filtration, as well as chemical technology products for diesel and gas-powered equipment around the world.

Q: How did Cummins Filtration get involved in supplying media for masks?

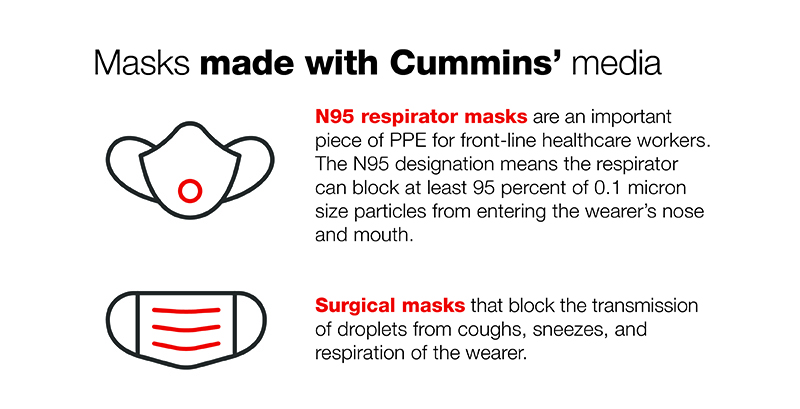

DAVIS: The need for masks, especially N95 respirator masks, skyrocketed in March and April in response to the COVID-19 pandemic. We learned that many of the world’s leading mask manufacturers needed the critical materials to assemble masks and were struggling to meet demand. We realized that the NanoNet® and NanoForce® Media technology typically found in filtration products for diesel engines could also be used in surgical masks and N95 respirator masks worn by healthcare professionals to help stop the spread of COVID-19. Once we made that connection, we began exploring partnerships to apply the filter material to masks.

Q: How has Cummins been able to partner with 3M in an additional effort to meet the surge in demand for PPE due to the COVID-19 outbreak?

DAVIS: We needed to move fast and saw an opportunity to use our existing workforce at our Neillsville, Wisconsin facility to meet this demand. We acquired, commissioned and tested a new pleater in a matter of weeks and have already produced more than 41,000 filters for 3M’s PAPRs since mid-April. Internally, we talk a lot about employee empowerment and decision making and this project is a testament to our employees’ ability to adapt quickly to fill an important supply void in a totally different market.

Q: What has the response been like from mask manufacturers?

DAVIS: Demand has been strong – in fact, it’s getting to the point where demand will exceed our capacity. Seeing so many organizations inquire about the media reinforced how critical the need for masks was globally. We’ve talked with Universities, health care systems, other automotive companies and mask manufacturers large and small about our media. To date, we’ve supplied 6 tons of the complete composite multilayer media that can be used in N95 masks, and we’ve shipped 8 tons of a simpler polypropylene media that can be used in surgical masks.

Q: Do you plan on selling media for masks long-term, or is this a temporary measure to respond to the COVID-19 pandemic?

DAVIS: We’ve added manufacturing capacity and capability to our plants and plan on continuing to supply media for masks as long as there is demand and a need to protect our communities from COVID-19.

Q: What has been the most interesting thing about this project for you?

DAVIS: Our employees always want to help, and it wasn’t a surprise when they demonstrated how quickly we could pivot from supplying filters for diesel engines to supplying the media that is critical to manufacturing medical PPE. It only took us one month to go from concept to production on this project! Cummins Filtration employees across the globe have taken immense pride in being part of the solution to help our communities, and the entire initiative is a great example of how Cummins embodies our mission of making people’s lives better by powering a more prosperous world.

Author Profiles

Cummins Inc., Global Power Technology Leader

Cummins Inc., a global power solutions leader, comprises five business segments - Components, Engine, Distribution, Power Systems, and Accelera by Cummins - supported by its global manufacturing and extensive service and support network, skilled workforce and vast technological expertise. Cummins is committed to its Destination Zero strategy - the company's commitment to sustainability and helping its customers successfully navigate the energy transition with its broad portfolio of products. Cummins has approximately 69,900 employees and earned $3.9 billion on sales of $34.1 billion in 2024. See how Cummins is leading the world toward a future of smarter, cleaner power at www.cummins.com.

Related Tags